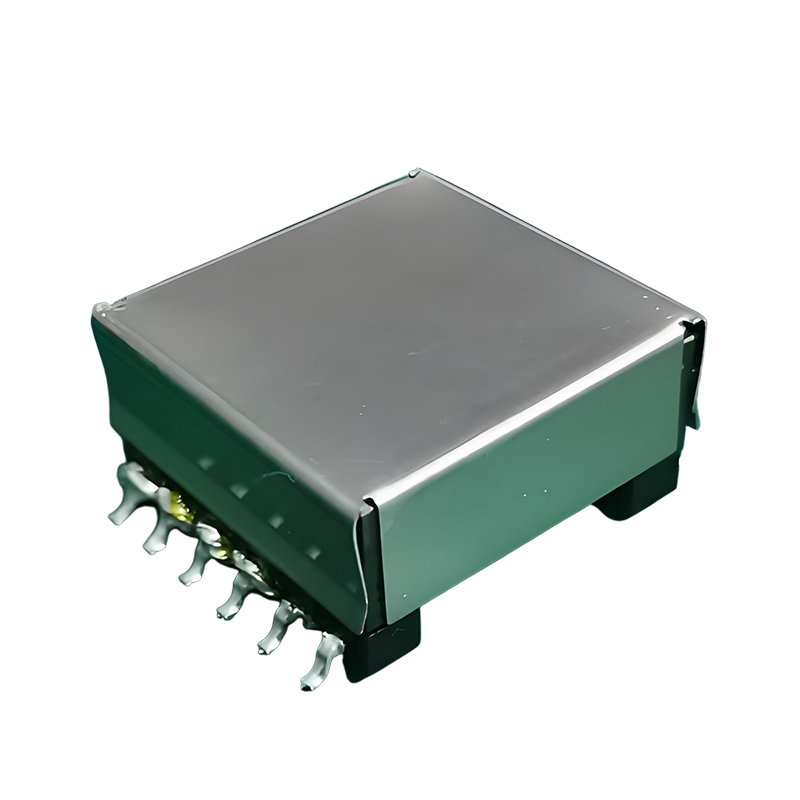

With the increasing trend towards thinner, smarter, and more energy-efficient modern electronic devices, the high-frequency transformer—a core component of power systems—is playing an increasingly crucial role.

- +86-13823000956

- Jobs.du@139.com

- Make Town 6A-2F,HongQi Town, Jinwan District, Zhuhai City, Guangdong Province