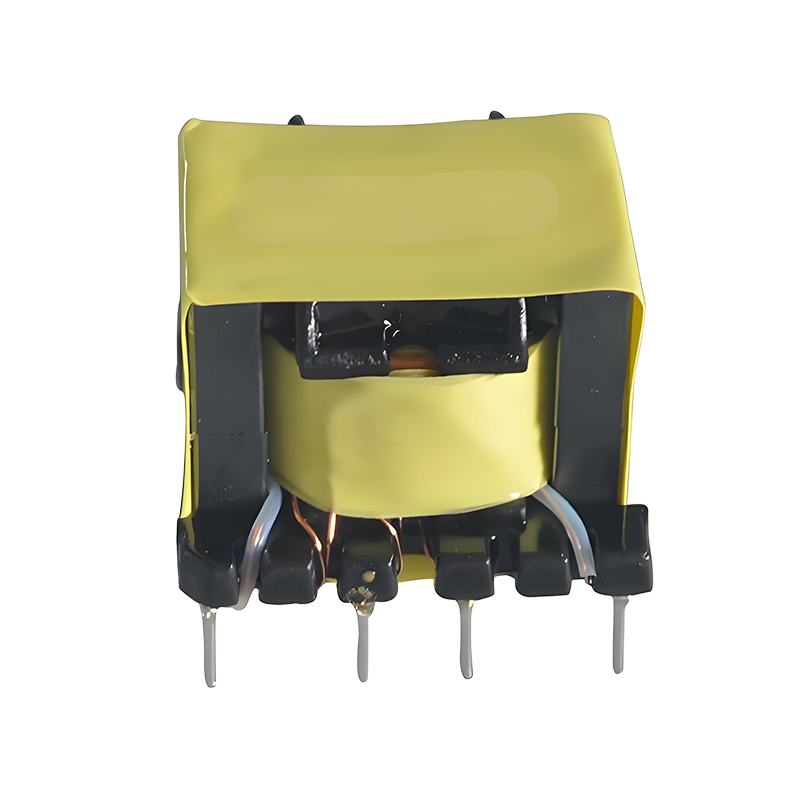

When there is a voltage difference between adjacent windings, the plate effect will form parasitic capacitance. Especially in high-frequency switching, repeated charging and discharging will aggravate energy loss.

- +86-13823000956

- Jobs.du@139.com

- Make Town 6A-2F,HongQi Town, Jinwan District, Zhuhai City, Guangdong Province